Clutch Release Bearing Burnout Symptoms:

Similar to farm tractors, the engine struggles to start when the clutch pedal is depressed. Turning the crankshaft with a hand crank feels extremely heavy. Releasing the clutch pedal and shifting to neutral allows the engine to start smoothly. At idle, depressing the clutch pedal immediately shuts off the engine.

After stopping and shutting off the engine for inspection:

Depress the clutch pedal and rotate the driven plate. The driven plate rotates freely, with no damage to other components. Pulling the clutch release bearing reveals it cannot move. Upon disassembly and inspection, corrosion due to inadequate lubrication is found. The inner and outer rings, along with the retaining ring and other parts, are severely corroded and seized. During operation, the bearing not only fails to rotate but also generates significant friction and abnormal noise with the clutch release lever, causing engine starting difficulties.

Common causes of release bearing failure include:

1. Although the release bearing is factory-lubricated with grease, prolonged use—especially under high temperatures—causes the grease to melt and gradually peel off during operation. The bearing then experiences dry friction and generates heat, leading to corrosion, seizure, and loss of separation function.

2. Some drivers habitually use the clutch in a partially engaged state. This keeps the clutch in a semi-engaged/semi-disengaged condition, causing dry friction and heat transfer from the clutch to the release bearing. This leads to grease loss within the bearing. When temperatures reach a certain threshold, the bearing can burn and become damaged.

3. During vehicle maintenance, if the small oil pan is missing or lost, dirt and debris may enter the release bearing, causing bearing wear.

4. Insufficient or absent clutch pedal free travel keeps the clutch in frequent engagement, causing fatigue damage or corrosion. Excessive pedal travel results in incomplete clutch disengagement and difficult shifting. The clutch remains partially engaged/disengaged, generating dry friction that transfers heat to the release bearing, causing grease leakage and bearing burnout.

5. Dust erosion of the release shaft causes grease degradation, accelerating damage.

6. Poor fit between the release bearing and release sleeve—particularly excessive clearance, looseness, or misalignment—subjects the release shaft to impact loads during operation, causing track wear and erosion.

The release bearing should rotate freely without abnormal noise (check method: axial clearance). Inner ring wear should not exceed 0.3mm; otherwise, replace with new parts. Excessive clearance exists between the pedal shaft, release fork, and bushings. Typically, bushings should be replaced and installed via grinding. When cutting two bushings on the bracket, use a long-blade cutter or guide blade to ensure concentricity.

When the engine is idling and the clutch pedal is depressed, if a “gritty” or “clinking” sound is heard, releasing the clutch pedal causes the sound to cease. Gently depressing the clutch pedal again (allowing the release bearing to contact the release fork) will cause the friction noise to reappear, indicating insufficient lubrication or wear of the clutch release bearing.

When disassembling and inspecting the release bearing, first unscrew the fixing screws and bolts securing the release lever to the transmission housing. Remove the release lever, then take out the release bearing assembly and retaining spring. Use a puller to extract the release bearing from the release bearing housing. Inspect the release bearing. If lubrication is insufficient, replenish it. If worn, replace it. When reassembling the release bearing, apply an appropriate amount of lithium molybdenum disulfide grease to the area indicated by the arrow on the release bearing housing. Avoid excessive application to prevent contamination of the driven plate.

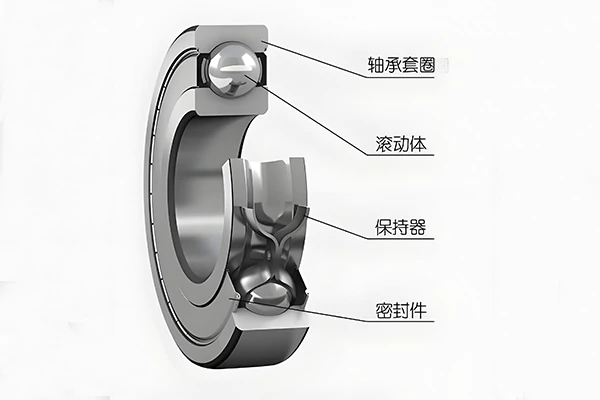

The release bearing typically employs an axial thrust ball bearing press-fitted onto the release sleeve. Lubricate the working surfaces of the release sleeve and release bearing by periodically adding grease or engine oil through a specially designed oil nipple mounted on the flywheel housing. Some release bearings utilize sealed, pre-lubricated bearings that must not be cleaned or lubricated with gasoline during disassembly and assembly. They only require wiping clean.

Corrosion and Damage of Clutch Release Bearings: Symptoms and Common Causes

Clutch Release Bearing Burnout Symptoms: Similar t…

Operating and Environmental Conditions for Spherical Roller Bearings

Properly determining the installation location, op…

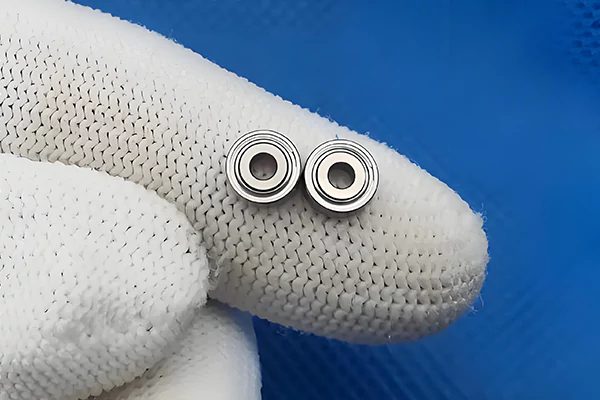

Miniature Bearings — Four Core Application Areas

Miniature bearings are suitable for various indust…

Failure Analysis of Engine Crankshaft Rolling Bearings

The crankshafts of some small wheeled tractors are…

Methods for Removing Bearing Inner and Outer Rings

It is well known that regular maintenance is essen…

Six Steps to Prevent Bearing Failures in Industrial Production

High-performance industrial bearings are critical …