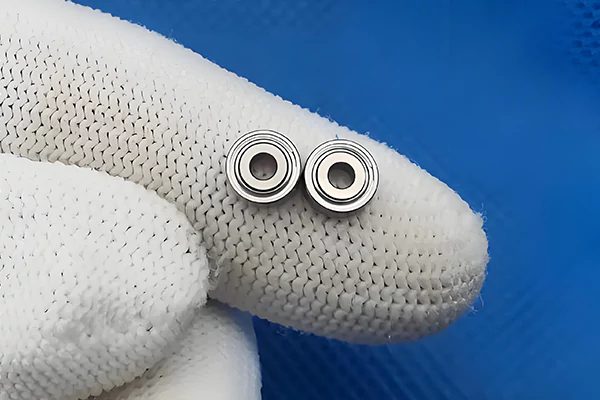

It is well known that regular maintenance is essential during bearing operation to achieve the expected performance. However, maintenance may require disassembling and reinstalling bearings to ensure continued proper functioning. To prevent bearing damage, proper methods must be used during disassembly.

Analysis of Bearing Inner and Outer Ring Disassembly Methods

To remove an outer ring with an interference fit, pre-install several outer ring compression screws around the housing circumference. For example, evenly tighten screws on one side of the printing press bearing during disassembly. These screw holes are typically covered with blind plugs, tapered roller bearings, and other separable bearings. Printing press bearings feature several notches on the housing cover shoulder, allowing removal using shims, a press, or gentle tapping.

The inner ring can be easily removed by pulling it out with a press. At this point, it is crucial to ensure the inner ring bears its tensile force. Additionally, pull-out clamps as shown are frequently used; regardless of the clamp type, it must be securely attached to the inner ring side. For this purpose, it is necessary to consider the dimensions of the shaft shoulder or investigate the machining of shoulder grooves to accommodate the pull-out fixture.

External Lecture on Disassembly Methods for Large Bearings and Cylindrical Roller Bearings

Large bearing inner rings are disassembled using the hydraulic method. By applying hydraulic pressure through the bearing's oil hole, press-fit bearings can be easily extracted. Bearings with large widths can be disassembled using hydraulic and drawing tools.

The inner ring of cylindrical roller bearings can be removed using the induction heating method. This involves heating a localized area for a short time to expand the inner ring, then pulling it out. The induction heating method is also employed when installing a large number of such bearing inner rings.

Corrosion and Damage of Clutch Release Bearings: Symptoms and Common Causes

Clutch Release Bearing Burnout Symptoms: Similar t…

Operating and Environmental Conditions for Spherical Roller Bearings

Properly determining the installation location, op…

Miniature Bearings — Four Core Application Areas

Miniature bearings are suitable for various indust…

Failure Analysis of Engine Crankshaft Rolling Bearings

The crankshafts of some small wheeled tractors are…

Methods for Removing Bearing Inner and Outer Rings

It is well known that regular maintenance is essen…

Six Steps to Prevent Bearing Failures in Industrial Production

High-performance industrial bearings are critical …