Welcome to FGFA bearings +86-13734455888

Welcome to FGFA bearings +86-13734455888

We always uphold the unremitting pursuit of excellent quality, rely on profound technical accumulation and fearless innovative spirit, and strive to carefully select precision bearings for customers around the world.

Learn More>

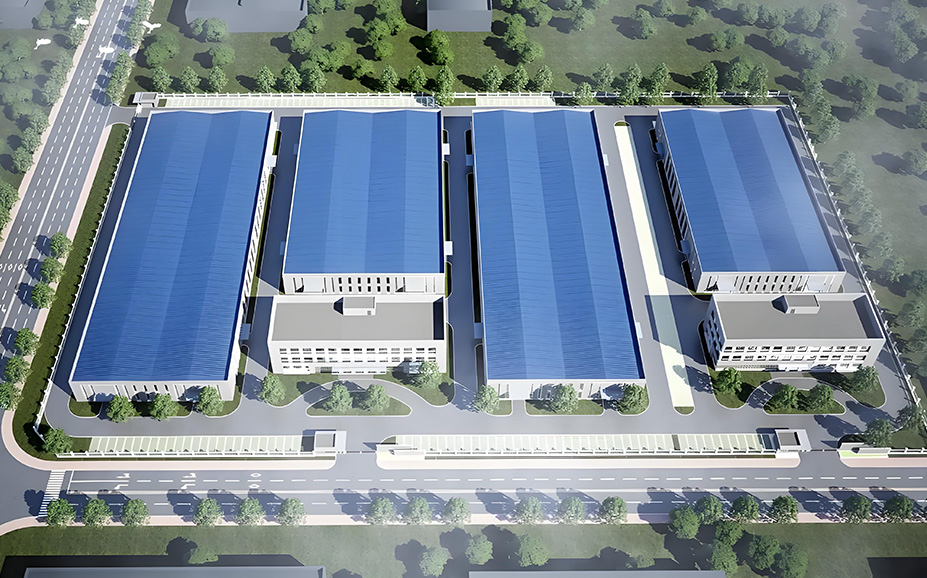

Based in the Wafangdian Bearing Industry Base, we are a medium-sized, specialized bearing manufacturer that combines flexibility and innovation, with a firm commitment to meeting customer needs.

FGFA Brand Introduction>

Wafangdian FGFA Bearing Co., Ltd., based in the Wafangdian Bearing Industrial Base, is a cutting-edge professional bearing manufacturer. Leveraging Wafangdian's rich heritage in the bearing industry, the company has, since its inception, centered its operations on craftsmanship, deeply integrating precision manufacturing principles into every aspect of product development and production. Its core focus lies in the in-depth research, development, and precision manufacturing of self-aligning roller bearings. Through precise structural optimization and meticulous refinement of materials and processes, the company's self-aligning roller bearings deliver exceptional radial load capacity and superior self-aligning performance. They reliably adapt to complex heavy-duty applications such as mining crushers, wind turbine gearboxes, and metallurgical rolling mills, demonstrating dependable operation in demanding industrial environments.

Supported by a precision manufacturing system, the company has established a comprehensive and diversified bearing production layout. It mass-produces a full range of products including deep groove ball bearings, self-aligning ball bearings, cylindrical roller bearings, angular contact bearings, tapered roller bearings, thrust ball bearings, spherical plain bearings, and spherical outer ring bearings.

Self aligning roller bearings, using symmetrical waist drum shaped rollers and brass retainers, have high load-bearing capacity, strong impact resistance, and automatic centering ability, suitable for heavy-duty scenarios such as mining, wind power, metallurgy, etc., supporting high-speed operation and customized needs, and are the core components for stable operation of heavy industrial equipment. Extra large split spherical self-aligning roller bearing, designed with a split structure, with connecting rings and fastening screws; Split installation can greatly save installation time; Cost saving: After a period of use, it can be flipped 180 degrees to continue using. Application areas: coal mining, papermaking, metallurgy, mining, steel mills, and various general machinery

The inner and outer raceway of angular contact ball bearings are offset relative to each other in the direction of the bearing axis. This indicates that this type of bearing is designed to carry combined loads, namely radial loads plus axial loads. The axial load-bearing capacity of angular contact ball bearings increases with the increase of contact angle. The angle between the line connecting the contact point between the steel ball and the raceway on the radial plane (i.e. the direction in which the combined load is transmitted from one raceway to another) and the perpendicular line of the bearing axis.

Cylindrical rollers are the core transmission components of bearings, with a cylindrical structure that adapts to the straight raceways of the inner and outer rings of the bearing. Their core advantages are large contact area and uniform load transmission. It has strong rigidity and excellent impact resistance, can efficiently withstand radial loads, adapt to medium and high-speed operation scenarios, and has low wear and long service life. Widely used in various types of bearing products such as cylindrical roller bearings and needle roller bearings, it provides stable transmission support for industrial equipment such as metallurgical equipment, motors, and machine tool spindles, and is a key component to ensure the bearing capacity and operational accuracy.

Conical roller bearings are transmission components designed specifically for composite loads, consisting of an inner ring, an outer ring, tapered rollers, and a cage. Through the adaptation of tapered raceways and rollers, they can simultaneously withstand large radial loads and unidirectional axial loads, with strong load-bearing capacity and high rigidity. The structural design is suitable for medium and low-speed heavy-duty working conditions, and the performance can be optimized by adjusting the clearance during installation. It is easy to maintain and widely used in scenarios such as automotive wheel hubs, machine tool spindles, engineering machinery, mining equipment, etc. It can stably transmit power in complex stress environments and is a key transmission component of industrial heavy-duty systems.

Thrust cylindrical roller bearings are transmission components designed specifically for heavy axial loads. They adopt a cylindrical roller structure, have a large contact area, strong load-bearing capacity, can withstand unidirectional or bidirectional axial forces, and are suitable for medium and low-speed heavy load conditions. High structural rigidity, stable transmission efficiency, easy installation and maintenance, widely used in heavy-duty scenarios such as metallurgical equipment, mining machinery, and ship transmission systems. It can accurately transmit axial forces under harsh working conditions, ensuring long-term stable operation of equipment.

Precision cross roller bearings are the core transmission components of high-end industrial equipment. With a unique 90 ° V-shaped groove cross roller arrangement structure, they achieve a perfect fusion of high precision, high rigidity, and high load-bearing capacity. They can simultaneously withstand radial and axial loads as well as overturning moments. The ultra-thin wall design greatly saves installation space and is suitable for the needs of compact precision equipment.

Thrust ball bearings are a type of transmission component specifically designed to withstand axial loads (forces acting along the axis centerline). The structure consists of a tight ring, a live ring, steel balls, and a cage, with the core advantages of strong load-bearing capacity and high transmission efficiency.

Thin walled bearings are compact transmission components with ultra-thin cross-sections. Their core advantages are lightweight, small space occupation, and the ability to achieve stable transmission within limited installation space. Compact structure, flexible rotation, suitable for high-speed operation scenarios, widely used in fields such as robots, medical equipment, aerospace equipment, etc. that have strict requirements for volume and weight, with both efficient load-bearing and low friction performance.

In the vast and challenging "starry sky" of the industrial sector, FGFA Bearings shines like the most brilliant and consistently radiant star. Relying on its extraordinary quality and the spirit of pioneering innovation, it proudly leads the entire industry forward with unwavering momentum.

Discover More>

Technical Consulting, Bearing Selection, Design, Service Life Calculation, Installation Guidance & Training, Bearing Inspection & Refurbishment, Spare Parts Service, Product Transformation & Upgrading, and Bearing Solutions.Services Create Value and Empower the Structural Transformation and Upgrading of China's Machinery Industry.

Manufacturing Strength>