Needle roller bearings are a type of rolling bearing that uses cylindrical rollers. These rollers are relatively thin and long compared to their diameter and are referred to as “needles.” According to the needle roller bearing model and specification table, common types include four categories: needle roller bearings without an inner ring, needle roller bearings with an inner ring, stamped outer ring needle roller bearings, and full complement needle roller bearings. Based on an understanding of the installation processes for these different types of needle roller bearings, the following sections will detail the specific installation methods for each category.

I. Installation Method for Full Complement Needle Roller Bearings

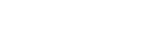

When installing full complement needle roller bearings, an auxiliary sleeve (or auxiliary roller) must be used. The function of the auxiliary roller/sleeve is to support the needles, preventing them from falling out, while the shaft neck uses its own chamfer to lift and position the needles. As the needle roller bearing is slowly moved inward onto the shaft journal, gradually withdraw the auxiliary roller/sleeve until the bearing is fully seated in its operational position. The outer diameter of the auxiliary roller/sleeve should be 0.1-0.3mm smaller than the shaft diameter. Prior to installation, apply grease to the inner surface of the bearing outer ring, then sequentially arrange the needle rollers tightly against this surface (leave clearance when placing the last needle); finally, complete installation by applying uniform pressure with a press or hammer.

Subsequently, push the auxiliary roller/sleeve (replacing the shaft neck or bearing inner ring) into the outer ring bore, aligning its end face with the shaft end face (or the end face of the bearing inner ring already mounted on the shaft).

II. Installation Method for Needle Roller Bearings with Inner Ring

First, apply a thin layer of lubricant to the outer diameter of the auxiliary sleeve. Insert it into the bearing outer ring to form an annular groove. Then, sequentially load the rollers into this groove. After all rollers are installed, use the working shaft to push out the auxiliary sleeve.

III. Installation Method for Needle Roller Bearings Without an Inner Ring/Outer Ring

During installation, apply a thin layer of grease to the rolling surface of the shaft or housing bore. Arrange the needles sequentially along the installation position, pressing them tightly against the grease to secure them in place. When inserting the final needle, leave a 0.5mm circumferential gap in the bearing. Never force the last needle into place, nor omit one: Forced insertion may cause the bearing to seize and become immovable. Insufficient needles create excessive clearance, leading to needle wobbling and breakage during operation.

IV. Installation Method for Stamped Outer Ring Needle Roller Bearings

Due to the thin outer ring wall thickness of stamped outer ring needle roller bearings, hammering is strictly prohibited during installation. Use a press for smooth press-fitting instead. Hammering causes uneven pressure, easily leading to localized deformation of the outer ring and compromising operational precision.

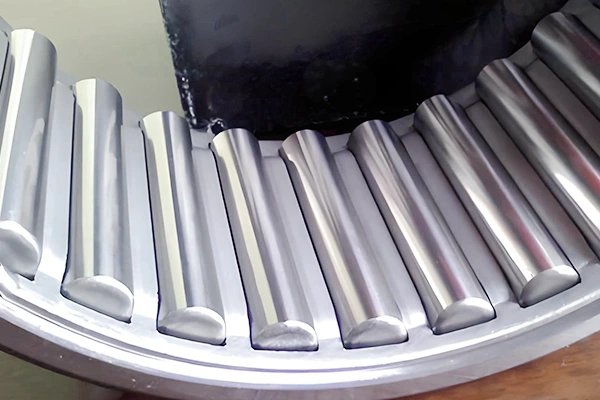

Needle roller bearings offer high load capacity and are suitable for support structures with limited installation space. Their shaft surfaces undergo quenching treatment to serve as rolling surfaces. Bearings are press-fitted into housing bores with interference fits. Note:

Additional axial positioning is required. Prior to installation, inject an appropriate amount of grease into the bearing interior. Typically, BK-type bearings require no further lubrication after assembly. This bearing type is suitable for shaft support scenarios without protruding shaft ends. Featuring a sealed end face design, it provides sealing effectiveness while accommodating minor axial displacement.

Bearing Maintenance and Repair

To preserve the original performance of rolling be…

Installation Methods for Different Types of Needle Roller Bearings

Needle roller bearings are a type of rolling beari…

Causes of Bearing Overheating and Troubleshooting

In the daily operation of industrial equipment, ab…

Material Selection Analysis for Wind Turbine Main Shaft Bearings

In wind power equipment, the main shaft bearing is…

What materials are used for automotive bearings?

In wind power equipment, the main shaft bearing is…

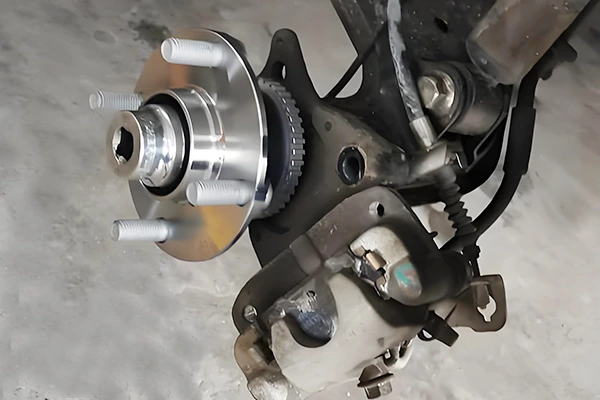

What are the commonly used materials for motor bearings?

The primary materials commonly used for motor bear…