In wind power equipment, the main shaft bearing is one of the core components ensuring the stable operation of wind turbines. To accommodate varying operational demands, manufacturers typically employ multiple materials for these bearings. Below are several common materials used for wind turbine main shaft bearings and their characteristics:

1. Steel

Steel is the most commonly used material for manufacturing wind turbine main shaft bearings. Common grades include 40Cr (alloy structural steel) and GCr15 (high-carbon chromium bearing steel). These steels offer excellent strength and hardness, effectively withstanding pressure and vibration during high-speed rotation. They also provide high cost-effectiveness, meeting the application requirements of most wind turbine main shaft bearings.

2. Heat-Resistant Steel

For bearings operating under high-speed, high-temperature conditions, heat-resistant steel is an ideal choice. This steel type exhibits good high-temperature strength and corrosion resistance. Varieties such as 9Cr18MoV (stainless steel) and H13 (hot-work tool steel) are widely used in such environments.

3. Reinforced Polymer Materials

Compared to traditional metals, reinforced polymer materials are favored for their lightweight, high strength, and wear resistance. They have been applied in bearing designs for small wind turbines. However, the strength stability of these materials requires further research and testing validation.

In summary, each material type for wind turbine main shaft bearings possesses unique advantages. In practical applications, the most suitable material must be selected based on specific environmental conditions and performance requirements.

Bearing Maintenance and Repair

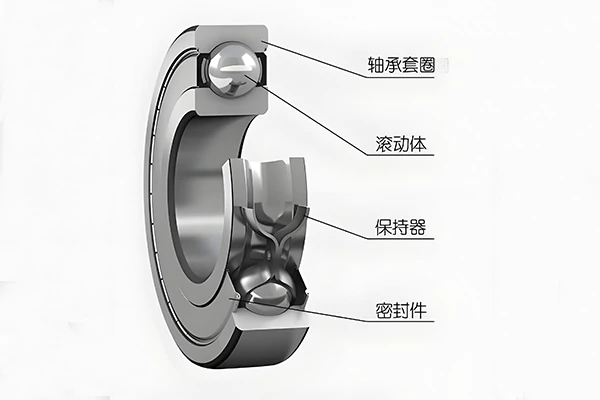

To preserve the original performance of rolling be…

Installation Methods for Different Types of Needle Roller Bearings

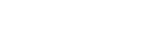

Needle roller bearings are a type of rolling beari…

Causes of Bearing Overheating and Troubleshooting

In the daily operation of industrial equipment, ab…

Material Selection Analysis for Wind Turbine Main Shaft Bearings

In wind power equipment, the main shaft bearing is…

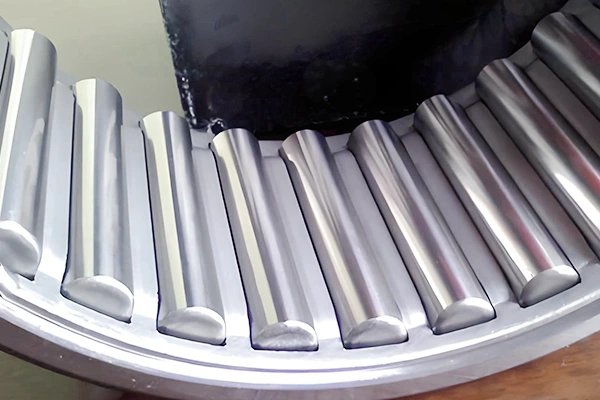

What materials are used for automotive bearings?

In wind power equipment, the main shaft bearing is…

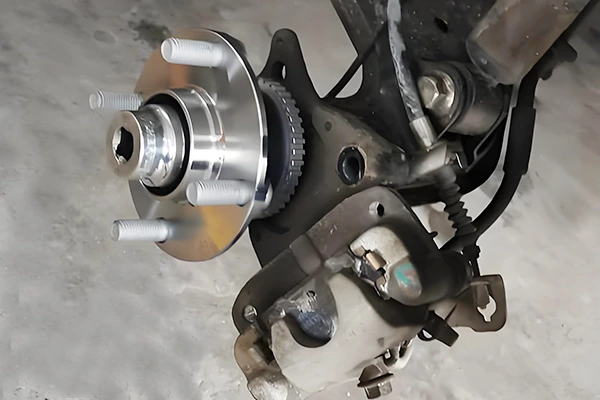

What are the commonly used materials for motor bearings?

The primary materials commonly used for motor bear…