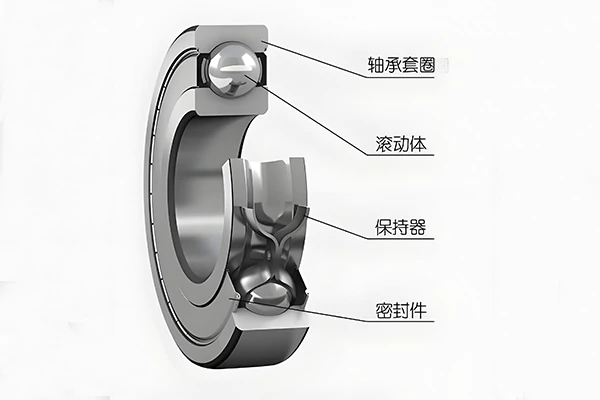

In the daily operation of industrial equipment, abnormal temperature increases in rolling bearings represent a common yet challenging issue. Like a hidden “time bomb,” if not promptly detected and addressed, it can trigger equipment failures and result in significant economic losses. This article delves into the core causes behind rolling bearing overheating and shares practical, efficient troubleshooting strategies.

I. Primary Factors Contributing to Bearing Overheating

1. Insufficient Lubrication: The Potential “Trigger”

Improper lubrication stands as a key factor in elevated bearing temperatures. When lubricant is inadequate, bearings lose essential protective lubrication during high-speed operation. Increased friction between rolling elements and raceways generates substantial heat. Furthermore, using incompatible or degraded grease diminishes its cooling and lubricating efficacy, driving up bearing temperatures. For instance, in high-temperature environments, certain lubricants may oxidize and degrade, failing to provide effective lubrication support.

Notably, poor lubrication and bearing temperature rise can form a vicious cycle: deteriorating lubrication conditions cause temperature increases, while elevated temperatures accelerate grease aging, worsening lubrication and driving temperatures higher. Therefore, regular lubrication system maintenance is critical for ensuring normal bearing operation.

2. Installation Errors: The Hidden “Saboteur”

Proper installation is equally vital for maintaining bearing performance. Deviations during installation—such as excessive tightness or looseness—disrupt the internal force balance of the bearing. Over-tightening reduces clearance between rolling elements and raceways, increasing friction resistance. Conversely, under-tightening causes wobbling during operation, intensifying vibration and friction, ultimately triggering overheating. Additionally, insufficient installation precision subjects bearings to extra stress, accelerating wear rates.

3. Material Defects: Inherent Weaknesses

Substandard bearings may harbor multiple flaws during production, such as insufficient material purity or subpar machining precision. These inherent issues cause abnormal wear and friction during operation, leading to heat accumulation. For instance, counterfeit or substandard products often exhibit poor raceway precision, preventing smooth rolling element movement. This significantly increases friction, inevitably generating excessive heat.

4. Overloading: Excessive Burden

The working load borne by bearings also influences temperature changes. When loads exceed rated limits, contact stress between rolling elements and raceways increases, causing heat generation. simultaneously accelerating the fatigue failure process. In practical applications, improper equipment parameter settings or prolonged overload operation can readily cause bearing overheating.

II. Targeted Inspection Plan

Upon detecting bearing overheating, conduct targeted inspections based on the above potential causes:

Assess lubrication status: First verify adequate lubricant quantity and appropriate grade. Inspect the grease condition, including color changes or signs of oil-water separation, to determine if replacement is necessary.

Re-examine installation quality: Verify correct bearing installation and eliminate issues like misalignment or looseness. Adjust excessively tight or loose installations as needed to ensure installation accuracy meets requirements.

Observe external damage: Check the bearing surface for visible wear, cracks, or other damage. Replace damaged components immediately upon detection.

Monitor operational load: Verify that equipment operating loads do not exceed bearing capacity limits. Adjust equipment parameters as needed to prevent overload operation.

During troubleshooting, prioritize inspecting the lubrication system status—this is the primary step in resolving bearing overheating issues and the easiest to quickly identify and rectify. Early detection and correction of lubrication problems can effectively prevent more severe equipment damage.

Bearing Maintenance and Repair

To preserve the original performance of rolling be…

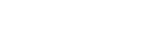

Installation Methods for Different Types of Needle Roller Bearings

Needle roller bearings are a type of rolling beari…

Causes of Bearing Overheating and Troubleshooting

In the daily operation of industrial equipment, ab…

Material Selection Analysis for Wind Turbine Main Shaft Bearings

In wind power equipment, the main shaft bearing is…

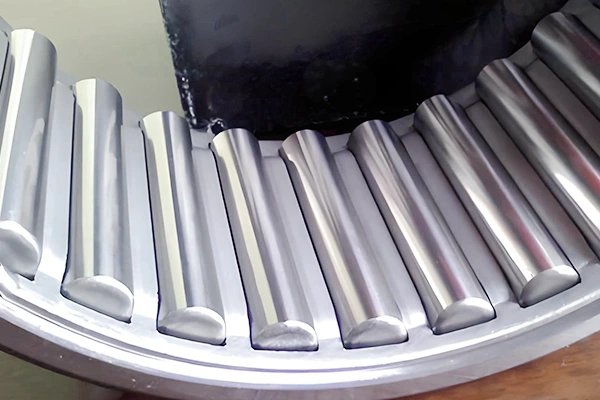

What materials are used for automotive bearings?

In wind power equipment, the main shaft bearing is…

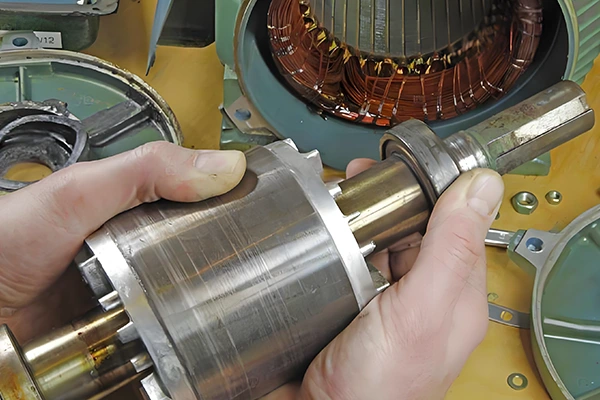

What are the commonly used materials for motor bearings?

The primary materials commonly used for motor bear…