The primary materials commonly used for motor bearings include the following categories:

Bearing Alloys: Bearing alloys, also known as white metals, are primarily composed of alloys containing tin, lead, antimony, or other metals. They feature excellent wear resistance, high plasticity, good running-in properties, superior thermal conductivity, and strong resistance to adhesion. Suitable for heavy-load and high-speed operating conditions, they exhibit low strength and typically require mounting on bronze, steel, or cast iron bearing shells.

Copper Alloys: Copper alloys include tin bronze, lead bronze, and aluminum bronze. Tin bronze offers the best anti-friction properties, making it suitable for heavy-duty and medium-speed applications. Lead bronze is ideal for high-speed and heavy-load bearings. Aluminum bronze possesses high strength and hardness, rendering it suitable for low-speed and heavy-load bearings.

Aluminum-based alloys: Aluminum-based bearing alloys offer good corrosion resistance and high fatigue strength, serving as partial replacements for expensive bearing alloys and bronzes. They are suitable for light-load, low-speed, and non-impact applications. Gray cast iron and wear-resistant cast iron: These materials possess moderate friction resistance and wear resistance, suitable for light-load, low-speed, and non-impact load conditions.

Non-metallic materials, such as plastics (e.g., phenolic resin, nylon, PTFE), are suitable for environments where chemical reaction is undesirable.

Application Scenarios and Selection Criteria for Motor Bearings:

Micro or small motors: Oil-impregnated bearings are typically chosen due to their minimal attachments, maintenance-free operation, and structural simplicity.

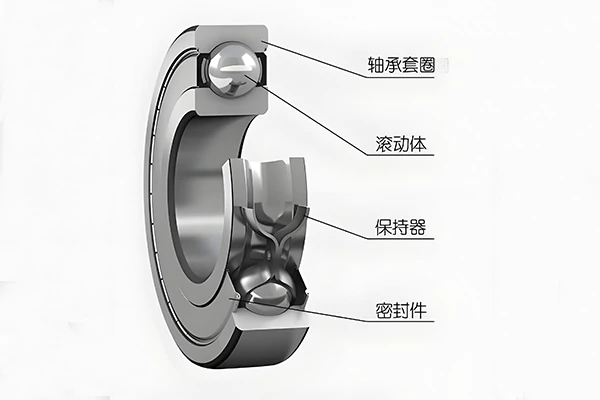

Medium to large motors: Plain bearings are suitable for heavy-duty and shock-resistant applications; rolling bearings are most widely used and suitable for diverse operating conditions.

Maintenance and care for motor bearings:

Lubrication: Rolling bearings are typically lubricated with grease or oil according to operational requirements.

Regular inspection: Periodically check bearing wear and promptly replace damaged bearings to ensure motor functionality.

These materials and selection criteria collectively ensure stable operation and extended service life for motor bearings under varying working conditions.

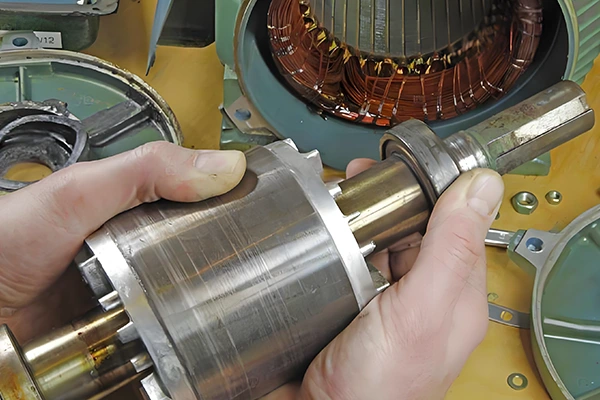

Bearing Maintenance and Repair

To preserve the original performance of rolling be…

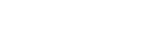

Installation Methods for Different Types of Needle Roller Bearings

Needle roller bearings are a type of rolling beari…

Causes of Bearing Overheating and Troubleshooting

In the daily operation of industrial equipment, ab…

Material Selection Analysis for Wind Turbine Main Shaft Bearings

In wind power equipment, the main shaft bearing is…

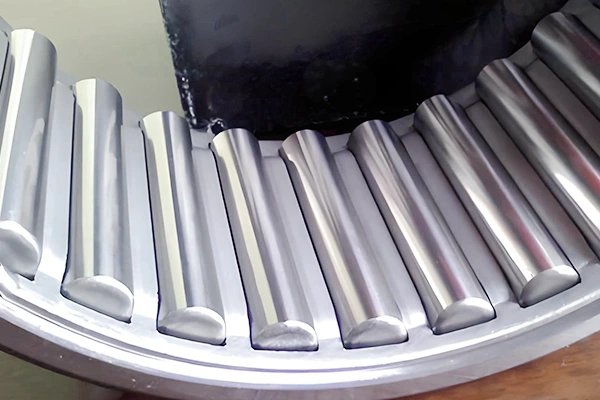

What materials are used for automotive bearings?

In wind power equipment, the main shaft bearing is…

What are the commonly used materials for motor bearings?

The primary materials commonly used for motor bear…