To determine whether a bearing can be reused, it is necessary to consider the extent of bearing damage, machine performance, criticality, operating conditions, inspection cycles, and other factors before making a decision.

During regular maintenance, operational inspections, and the replacement of peripheral components, bearings that are removed should be examined to determine if they can be reused or if their condition is acceptable or unacceptable.

First, it is necessary to carefully inspect and document the disassembled bearings and their external appearance. To determine and investigate the remaining lubricant quantity, the bearings should be thoroughly cleaned after sampling.

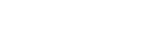

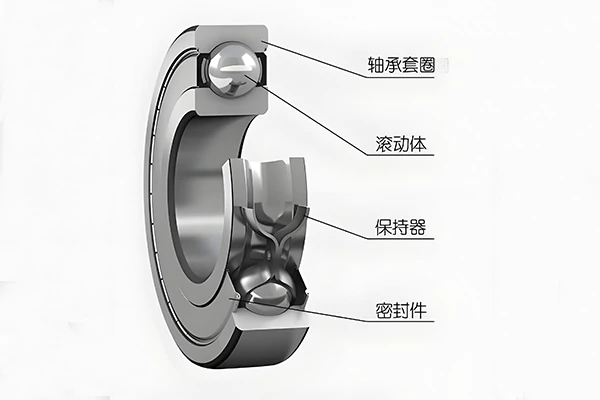

Second, examine the condition of the raceway surfaces, rolling surfaces, and mating surfaces, as well as the wear state of the cage for any damage or abnormalities.

To determine bearing reusability, factors such as damage severity, machine performance, criticality, operating conditions, and inspection intervals must be considered before making a decision.

If damage or abnormalities are detected during inspection, identify the cause at the damaged section and develop countermeasures. Furthermore, based on inspection results, bearings exhibiting any of the following defects cannot be reused and require replacement:

a. Cracks or fragments present in any of the inner ring, outer ring, rolling elements, or cage.

b. Flaking of the inner ring, outer ring, or rolling elements.

c. Obvious seizure damage on the rolling surfaces, flanges, or rolling elements.

d. Severe wear of the shield or loosening of rivets.

e. Rust stains and scratches on the raceway surfaces or rolling elements.

f. Obvious indentations or marks on the raceway surfaces or rolling elements.

g. Creep deformation on the inner ring bore surface or outer ring outer diameter.

h. Severe discoloration due to overheating.

i. Serious damage to the seal or dust cover of sealed bearings.

Inspection and Troubleshooting During Operation

Operational inspection items include bearing rolling sound, vibration, temperature, lubrication status, etc. Specific details are as follows:

Bearing Rolling Sound

Use a sound detector to assess the volume and timbre of rolling sounds from operating bearings. Even minor spalling or damage produces abnormal, irregular noises detectable by the sound detector. Bearing Vibration

Bearing vibration is highly sensitive to damage such as spalling, indentations, rust, cracks, or wear, all of which manifest in vibration measurements. Therefore, by using specialized bearing vibration measurement instruments (such as frequency analyzers), the amplitude of vibration can be measured, and the specific nature of the abnormality can be inferred through frequency differentiation. Measurement values may vary depending on bearing operating conditions or sensor mounting positions. It is necessary to analyze and compare the measurement values for each machine in advance to establish judgment criteria.

Three Bearing Temperatures

The temperature of a bearing can typically be inferred from the external temperature of the bearing housing. If the outer ring temperature can be measured directly through the oil hole, this is preferable. Generally, bearing temperature gradually increases as operation commences, reaching a stable state after 1-2 hours. Normal bearing temperatures vary depending on the machine's thermal capacity, heat dissipation, speed, and load. If lubrication and component installation are appropriate, a sudden rise in bearing temperature may occur, leading to abnormally high temperatures. In such cases, operation must be halted immediately and necessary preventive measures taken. By employing thermal sensors, bearing operating temperatures can be continuously monitored. When temperatures exceed specified limits, automatic alarms or shutdowns can be triggered to prevent shaft accidents.

Bearing Maintenance and Repair

To preserve the original performance of rolling be…

Installation Methods for Different Types of Needle Roller Bearings

Needle roller bearings are a type of rolling beari…

Causes of Bearing Overheating and Troubleshooting

In the daily operation of industrial equipment, ab…

Material Selection Analysis for Wind Turbine Main Shaft Bearings

In wind power equipment, the main shaft bearing is…

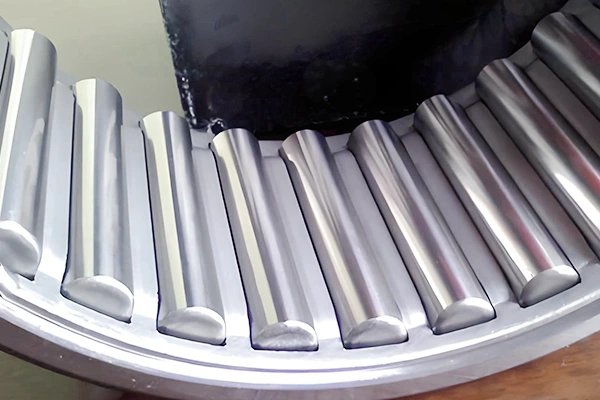

What materials are used for automotive bearings?

In wind power equipment, the main shaft bearing is…

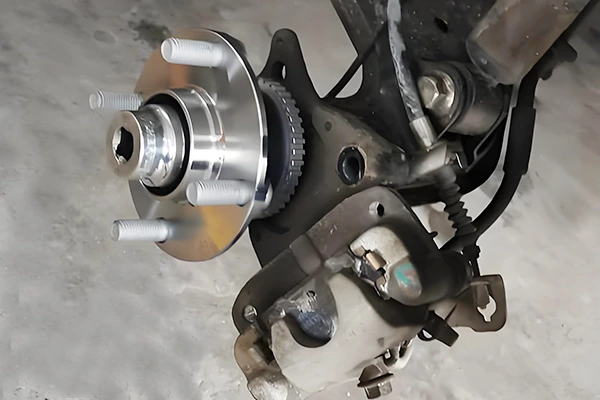

What are the commonly used materials for motor bearings?

The primary materials commonly used for motor bear…