Excessive oil content in bearings and housings can cause bearing slippage.

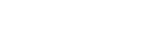

Excessive oil content in self-aligning roller bearings and housings can cause the rolling elements of self-aligning roller bearings to slip, transforming rolling friction into sliding friction and damaging the rolling components of self-aligning cylindrical bearings. Due to excessive oil content in self-aligning bearings, the limited free space within the housing causes elevated operating temperatures in self-aligning tapered roller bearings. This reduces grease frequency, thins the lubricating oil film on rolling elements, and degrades lubrication conditions. Consequently, abnormal noise and surface slippage may occur, shortening the service life of self-aligning bearings. Typically, one end cover side of the self-aligning roller bearing features an oil chamber (excluding double-sealed self-aligning roller bearings). Based on rotational speed, the oil filling volume for the self-aligning roller bearing chamber should adhere to the following standards: When rotational speed is below 1500 r/min, the oil volume should be 2/3 of the bearing chamber volume. For speeds between 1500 and 3000 r/min, it should be 1/2 of the chamber volume. When speed exceeds 3000 r/min, the oil volume should be less than or equal to one-third of the bearing chamber volume. In practical applications, for self-aligning roller bearings operating under high-temperature and high-speed conditions, it is recommended to minimize the use of sealed-face self-aligning roller bearings, increase the oil reservoir capacity of the oil cover, and install oil injectors to extend the service life of the self-aligning roller bearings.

Foreign object intrusion readily causes bearing failure.

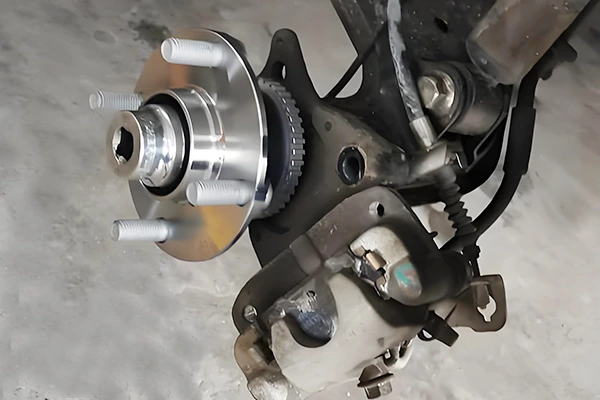

Foreign object intrusion. Use specialized tools whenever possible and avoid fabrics and short fibers to prevent fine fibers from entering the self-aligning roller bearing and causing unnecessary damage. For example, during self-aligning roller bearing installation, workers employing the copper rod tapping method can cause uneven axial forces on the bearing. This leads to cage deformation, rolling element damage, and increased clearance. Copper particles generated during tapping can enter the bearing cage, readily causing failure. What are the drawbacks of improper bearing installation? Self-aligning roller bearings must be installed following proper procedures to avoid rough handling during mounting and disassembly. Correct installation directly impacts the bearing's service life, so meticulous attention is essential. When installing self-aligning roller bearings, avoid direct handling with bare hands, as skin oils can cause corrosion. Do not overlook minor details. During installation, the most critical points are: never forcefully press the bearing into place, and never strike the self-aligning roller directly with a hammer. The concern is not damage but deformation. Once deformed, the self-aligning roller bearing becomes unusable. Additionally, pressure must never be transmitted through the rolling elements.

Bearing Maintenance and Repair

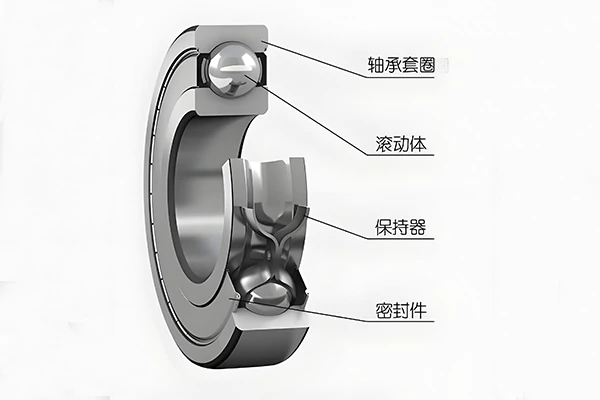

To preserve the original performance of rolling be…

Installation Methods for Different Types of Needle Roller Bearings

Needle roller bearings are a type of rolling beari…

Causes of Bearing Overheating and Troubleshooting

In the daily operation of industrial equipment, ab…

Material Selection Analysis for Wind Turbine Main Shaft Bearings

In wind power equipment, the main shaft bearing is…

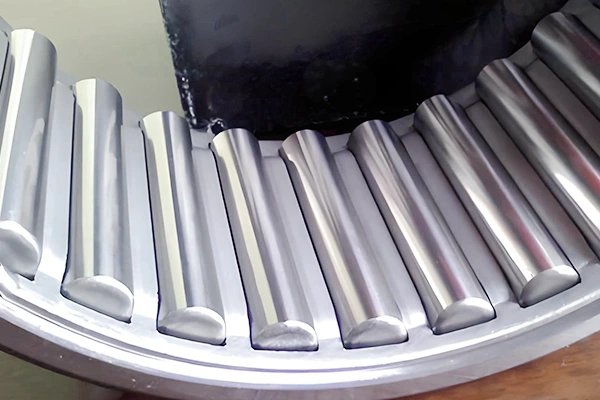

What materials are used for automotive bearings?

In wind power equipment, the main shaft bearing is…

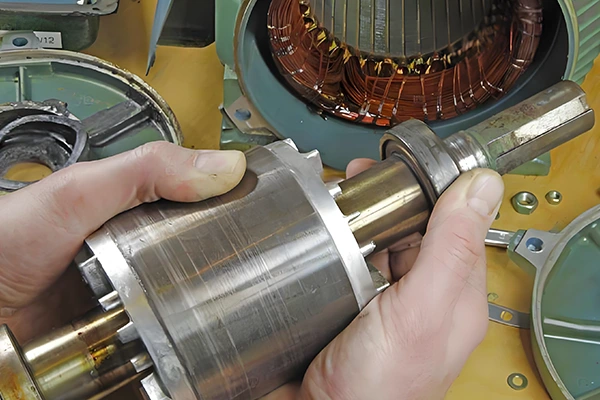

What are the commonly used materials for motor bearings?

The primary materials commonly used for motor bear…