Advancements in turbine technology have driven demand for high-performance components, strengthening the connection between the wind power generation industry and the bearing sector. Recent reports indicate that the global push for renewable energy has led to a surge in wind turbine installations, necessitating innovative bearings capable of withstanding the demanding conditions of wind power generation. Manufacturers are focusing on developing bearings that enhance durability and efficiency, which are critical for reliable turbine operation. With the market projected to expand significantly in the coming years, companies are investing in R&D to create lightweight, corrosion-resistant bearings that optimize energy output and reduce maintenance costs.

Furthermore, collaboration between wind power developers and bearing manufacturers is becoming increasingly common, as both sectors recognize the importance of reliable components in maximizing turbine lifespan and performance. As the world shifts toward sustainable energy, synergies between the wind power and bearing industries are expected to strengthen, creating new opportunities for innovation and economic growth. The future of clean energy undoubtedly hinges on the strength and reliability of these critical components.

Bearing Maintenance and Repair

To preserve the original performance of rolling be…

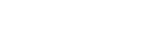

Installation Methods for Different Types of Needle Roller Bearings

Needle roller bearings are a type of rolling beari…

Causes of Bearing Overheating and Troubleshooting

In the daily operation of industrial equipment, ab…

Material Selection Analysis for Wind Turbine Main Shaft Bearings

In wind power equipment, the main shaft bearing is…

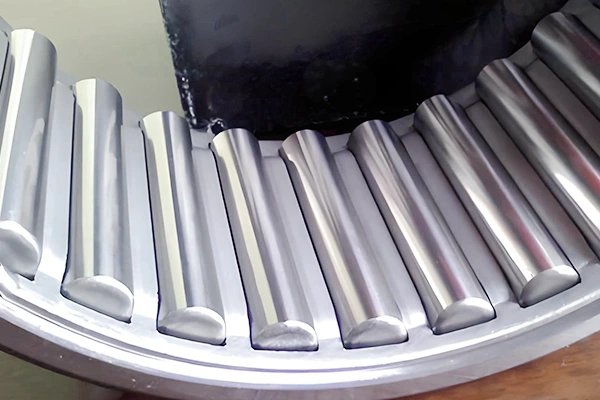

What materials are used for automotive bearings?

In wind power equipment, the main shaft bearing is…

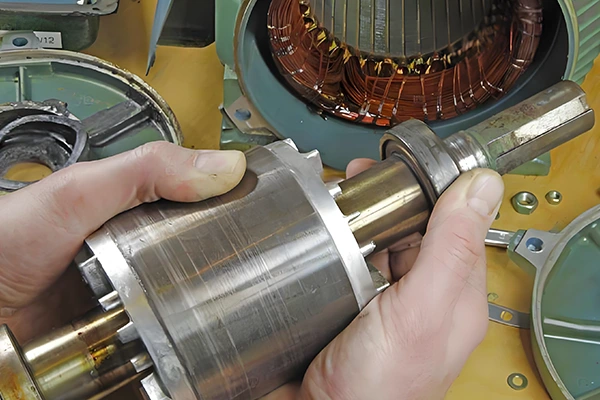

What are the commonly used materials for motor bearings?

The primary materials commonly used for motor bear…